| About business |

|---|

| Pipe production |

| Surface treatment |

| Visiting service |

| Painting |

| R&D |

Our factories are fully equipped with surface treatment & paining facilities. We have built integrated production system which is from pipe production, surface treatment, painting, and efficiency of transportation. We response not only turnkey contract from pipe production, surface treatment and painting, but also each needs and visiting service. We take care of matters as they come. By integrated production system, We do short deadline, simplify procedures, low logistic cost.

Pipe production

We produce mainly 15A-400A pipes which are handled at shipyard. In these year, we also response needs for plant&engine and expand our business area to diversified small-quantity production.

Certification

Lloyd's Resister (C/S, Vessel)

Welder certification

| Certification | Type |

|---|---|

| Class NK (vessel) | CS SA-2V |

| TN-2P | |

| JIS (plant) | CS SA-2F |

| SC-2F | |

| SC-2P | |

| SUS TN-P | |

| Lloyd (Vessel) | WQ01 D+Vu+0 |

| WQ01 D+Vu |

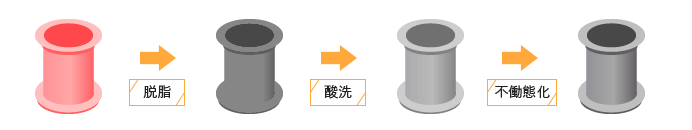

Surface treatment

Acid cleaning

Create added value from rust-preventative treatment, passivate film and improvement durability&mechinability by removal pollutant, impurities. Acid cleaning is our main technology and know-how intensive area about surface treatment. In recent year, cleaning line longest which is biggest line on west japan 12m has been completed.

Steel products

Build a rust-preventative film for each purpose by removal foreign substance

Main process

Various treatment such as 'Degreasing' removing oil, varnish, paint, 'Acid cleaning' removing rust, mill scale, gilding. We treat a diversity of rest-preventative treatments such as 'Phosphate film treatment', 'Alkali rust-preventation treatment' which is excellent for rust-preventation, 'Zinc phosphate film treatment' which is excellent for pain-adhesion, 'Manganese phosphate film treatment' which is good for mechanical sliding.

Subject area

Nonferrous metal products

Bring back original appearance, Build an anti-corrodible film on passive state metals

Main process

We treat passivation treatment on various sized pipes by chemical precipitation, chemical paste adsorption method to remove oxide inclusion scale, oil and impurities etc.

Subject area

Stainless steel

Additional nonferrous metal (Titanium alloy, Copper alloy etc.)

Additional material (Ceramic, Resin)

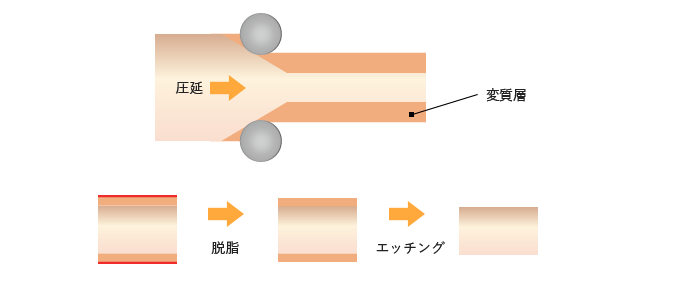

Etching

we remove trans-phase on metal surface caused by cold-formed

Subject metal

Stainless steel, Titanium alloy, Aluminum alloy

Way of trans phase caused by cold-formed

Polishing

We response mainly chemical polishing by special chemistry, beside electrolytic polishing, buffing grouts.

Subject metal

Stainless steel, Titanium alloy, Aluminum alloy

Gilding

We do electroplating of zinc, nickel, copper, tin, chrome, gold, silver and nickel-electro less plating.

Cleaning a precision instrument

Regarding cleaning a precision instrument requiring high know-how, we clean by ultrasonic cleaner or cleaning in clean room.

Subject area

Visiting service

We response visiting service with high-pressure washer, chemistry and gathering tank of waste by customer's request. Not only domestic experience, but we have visiting service experience aboard such as Mexico and Singapore. Regarding customer's needs, we suggest produce and sort of quality test. One of our experience at chemical plant, we analyzed the sample of impurities at our lab and suggested optimum chemistry and produce based on the result and development. At the result, we received a favorable evaluation

Processing content

Subject area

Painting

We suggest foundation treatment according to the material of pipes or structure which is used at vessel and plant. Those material can be improved fine exterior and durability by painting what we do on customer's demand of spec.

Subject area

R&D

Response to needs of our customer is our moto of R&D. Our R&D suggest latest technology based on their own comprehensive result of quality test, experiment, analysis, produce about the subject what our production spot face the difficult task of with specialized equipment in our lab on 3th floor of our head office. Regarding development order, we decide optimum new development, improvement, produce based on beaker experiment. Then we make final proposal after we repeat pilot production in our factory and evaluation. In these later years, we cooperate with national research institute or collaborate with R&D team of other makers.

Analysis equipment

| Name of equipment (model, standard) |

Purpose |

|---|---|

| Surface observation | |

| Scanning electron microscope (10000magnification) | Observation of product inside or expansion particle shape |

| Energy dispersive X-ray fluorescence spectrometer | Microelement analysis and distribution state measurement |

| Electron microscope (RH-2000 1~2500magnification) |

Expansive observation of surface |

| Spectrophotometry (CM-700d) |

Color difference of products |

| Toughness analyzer of surface (SJ-201) |

Analyze toughness of surface |

| Component analysis | |

| Spectrophotometer (UV-1800) |

Quantitative&qualitative analysis of components in a solution |

| Ion Chromatography analyzer (Bionex Integrion negative ion analysis system) |

Quantitative&qualitative analysis of negative ion in a solution |

| Electrochemistry measurement system (HZ7000 HAG1232m) |

Quantitative&qualitative analysis of ion or residual substance in a solution |

| X-ray fluorescence spectrometer (EDX-800 6C~92U) |

Quantitative&qualitative analysis of sample |

| et cetera(etc.) | |

| Instrumentation device of hydraulic fluid's pollution level (YC-100-21) |

Cleanliness instrument of hydraulic fluid, lubricant |

| Pure water manufacturing equipment (WGH200distilled pure water over 18MΩ・cm) |

Manufacturing distilled water for analysis or experiment |

| Particle counter system in solution (KS-42D、KZ-30W、KE-40B1) |

Measure mount of particle in pure water or solution |

| Rotary salt spray test instrument (SQ-800ST) |

Corrosion resistance speeding test of surface |

Sales presentation

KISUKE (Chemistry to remove rust for gasoline tank)

|

This solution is convenient neutral anti-rust additives

Contact |

|

|---|